Support Center

Bottom Paint

To prevent marine growth and increase the longevity of the components, the Seakeeper Ride Controllers may be coated in antifouling paint, also known as bottom painting. This is recommended if the boat will be in the water for more than two (2) weeks at a time. Follow the instructions in this document to ensure the best results when bottom painting Seakeeper Ride.

Choose a bottom paint that best fits the usage and storage of the boat. Avoid paints that contain metals for biocide, as they may cause corrosion damage to the stainless steel and aluminum components. Spray-on paints are easier than roll-on but may take more prep time to prevent overspray on undesired surfaces.

To bottom paint Seakeeper Ride Controllers:

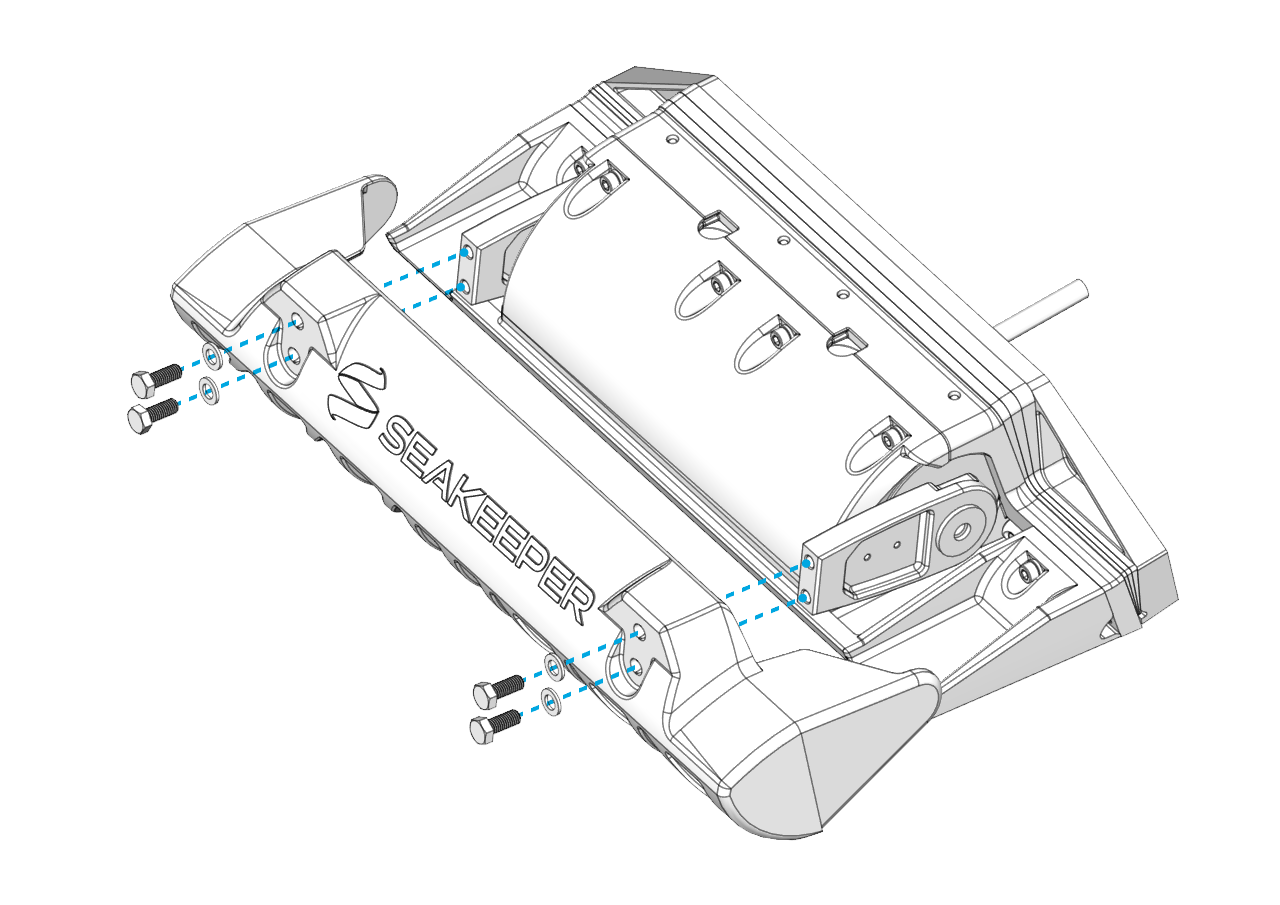

- Remove the Blade by unscrewing the four (4) M8-1.25 x 20 mm screws and their washers.

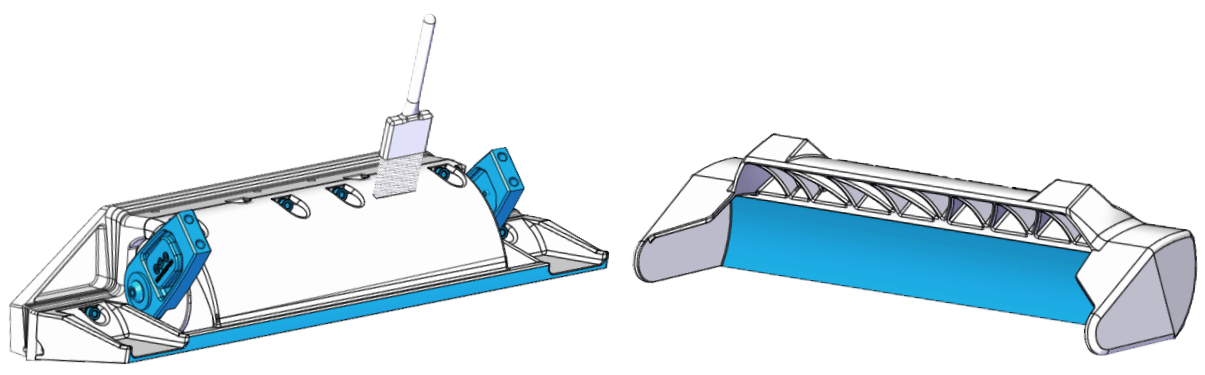

- Use masking tape to cover surfaces that will not be painted. This includes the inside of the Blade, trailing edge of the Seal Plate, stainless steel hardware and arms, and any part of the boat that will be left unpainted. Controller components that should be protected with tape are shown in blue in the figure below.

- Follow the instructions and recommendations associated with the paint being used for surface preparation on the SMC parts (Seal Plate, Blade, Actuator Plate, Wedge Plates, and Transom Plate) supplied. The SMC parts are similar to fiberglass in that they are a fiber reinforced plastic. As such, the surface can be sanded and wiped with solvents like acetone to prepare them for paint adhesion. Be careful not to gouge, cut, or sand deeply into the SMC parts. Removing too much material will reveal the reinforcing fibers and could reduce their structural strength.

Do not sand or scuff the stainless steel torque arm or aluminum body of the Actuator. Do not scuff or alter the inside of the Blade or trailing edge of the Seal Plate. The gap between these surfaces is precise and must remain at factory fitment. Surfaces that must not be scuffed are shown in blue in the figure above.

- Apply the selected bottom paint to the Blade and the rest of the Controller assembly. Do not paint the inside of the Blade and trailing edge of the Seal Plate. Adding paint to these surfaces will cause the parts to contact during operation and greatly reduce system performance. Avoid painting the stainless steel hardware and arms. Surfaces that must be left unpainted are shown in blue in the figure above. Paint all other accessible surfaces.

- Reattach the Blade using the four (4) M8-1.25 x 20 mm screws and their washers. Be sure to use thread locking sealant with an activator/primer when reinstalling hardware. Torque these four (4) bolts to 80 in-lbs (9.0 N-m) in an “X” pattern.

Recommended Paint Products

Seakeeper has done testing with several anti-fouling products to determine how well they adhere to the SMC material. Seakeeper has not tested the performance of each coating system’s ability to prevent growth as it is largely dependent on water, climate, and boat usage. We did, however, test the adhesion of several available products on our SMC components. We found these paints and preparations to adhere to the SMC and hold up to pressure washing:

Seaspeed VX10 (only 1 procedure was recommended)

- Spray or wipe down parts with isopropyl alcohol

- Sand lightly with 180 grit sandpaper

- Apply Sea-Speed with HVLP Gravity feed spray gun, tip size 1.6mm

- Apply at 125 microns of wet film thickness

Interlux – Trilux 33 and Auqa tested

- Clean surfaces with Interlux 202 solvent

- Spray 2 coats of Trilux 33 or Aqua

Seahawk Cukote

- Clean with S80 wax and grease killer

- Sand with 180-grit sandpaper

- Seahawk 1266 Primer

- Seahawk Cukote paint

Pettit HRT Eco

- Pettit Bottom Prep D95

- Sand with 180-grit sandpaper

- 1 coat sprayed of Pettit Protect 470 Primer

- 2 coats sprayed of Pettit HRT Eco

We have not tested the options below, but contacted the manufacturers, who recommended the following systems and preparations:

Seahawk

- Sand SMC parts with 180-grit sandpaper

- Wipe with acetone

- Apply 2 coats of Seahawk Tuff Stuff 2-part epoxy primer

- Apply 1 coat of Seahawk Monterey Water Based Ablative antifouling

Pettit Paint

- Wipe all surfaces with acetone

- Rough up SMC parts with 60-grit sandpaper

- Prime SMC and Stainless with Pettit Protect Primer 4700

- Prime exposed aluminum (Actuator) with 3 coats of Pettit Protect Primer 4700

- Finish coating with:

- Good – HRT ECO

- Better – Vivid

- Best – Odyssey Triton

Interlux

- Clean surfaces with Interlux 202 solvent

- Sand SMC surfaces with 80-grit sandpaper

- Apply 4 coats of Interprotect 2000E

- Apply 3 coats of Micron CSC